Galvalume Chemicals

Galvalume Chemicals

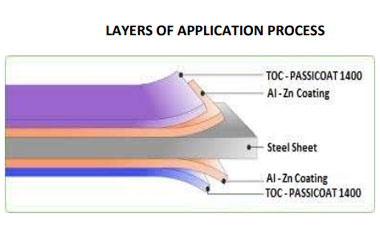

Galvalume is a process of imparting a sacrificial aluminum-zinc coating on the iron or steel surface, thereby protecting the surface from atmosphere. Method of application differs according to the need and availability of measures. Thin Organic Coatings (TOC’s) are applied in a continuous process on hot-dip galvanized steel strip, Galvalume®, Aluzinc. TOC’s can offer a wide range of benefits; from anti fingerprint properties to improving forming, increasing mechanical scratch resistance, and enabling enhanced corrosion protection. TOC is an efficient solution for any application where traditional passivated galvanized material is used, especially in rust sensitive conditions. It is suitable for interior, exterior, exposed and unexposed parts without any additional surface treatment. If necessary, steel with TOC can also be painted.

MAJOR STEPS:

ALKALINE CLEANING – Removing oil, grease and soil from steel surface is crucial, otherwise, dissolution of iron oxide / scale by pickling will be retarded.

DEGREASING CHEMICALS FOR GALVALUME

PASSIVATION WITH TOC (THIN ORGANIC COATING)

Thin Organic Coating (TOC) chemical is formulated for continuous galvalume line application. It forms an organic coating on treated surface that supports an anti-fingerprint property as well as better corrosion resistance.

BENEFITS OF THIN ORGANIC COATING

- Exceptional corrosion resistance.

- Anti-fingerprint.

- It delays appearance of white rust.

- Increases galvanized steel durability.

- Keeps galvanized surfaces bright and shiny for extended periods of time.

- Savings in customer claims.

- Provides the ability to store galvanized products outdoor.

- Savings in indoor space for other activities.