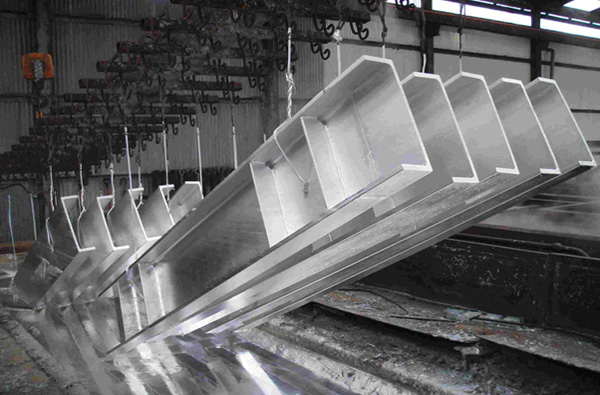

Tube and Struture Galvanizing Chemicals

The importance of protecting from corrosion articles used in open environment made of plain steel, such as structures and tubes etc., is obvious, and coating the steel surface with a thin layer of a corrosion resistant metal is a most convenient means of protection, best applied as a final operation in the manufacture of these products. Of all the metals used for the purpose of protection against corrosion, zinc is one of the cheapest and the one most widely used, being suitable for nearly every kind of article, except food containers. Use of zinc is not only cheaper and easy to coat but it also protects iron or steel by providing cathodic or sacrificial protection.

DEGREASING CHEMICALS

Mainly steel tubes / structures are galvanized in this method.

Degreasing – Removing oil, grease and dirt from steel is crucial to good galvanizing. Without this process acid pickling will be disturbed and a patchy zinc coating will form after galvanizing.

DEGRISOL 1107 ( Alkaline Degreasing )

It is a strong alkaline cleaner used for dip degreasing of steel articles before structure and tube galvanizing.

PHOSCLEAN 151 (Acid Degreasing)

An advance azole based liquid formulation to control corrosion in open re-circulating cooling water systems with copper & copper based metallurgy.

DEGRISOL 2126 (Acid Degreasing)

It is an ortho phosphoric acid-based degreasing chemical that acts at acidic pH and allows the oils and greases to form clumps and sediment at the bottom.

ACID PICKLING INHIBITOR CHEMICALS

Ferrous metals have a surface coating of metallic oxide or scale which must be removed before the zinc coating can be applied successfully. The most common process for removing this film is called pickling. Pickling involves immersing the work in an acid to dissolve the scale or oxide film. Many acids can be used; the most common for galvanizers is hydrochloric acid.

FERROGUARD 358

It is a powerful acid inhibitor used in hydrochloric acid pickling baths. It forms a thin foam blanket on the surface of the pickling baths and thus minimizes fuming.

FLUXING CHEMICALS

A property of the preflux bath is that it makes a thin coating on metal surface which prevent further rusting and at the time of galvanizing it removes the oxide layer from the surface and confirms the zinc metal adhesion.

FLUXOL 339 ( WET FLUX)

It is used as wet flux. It is in powder form and applied by making a solution by dip prior to galvanising. After pickling the rinsed articles are dipped into a solution of FLUXOL 339 and dried completely prior to dipping into the molten zinc bath.

FLUXOL 344 (NICKEL BASED )

It is used as a specially formulated wet flux with Nickel Additive. It is in powder form and applied by making a solution and dipping the cleaned articles in the solution of FLUXOL 344.

.

FLUXOL 340 (WATER FLUX)

It is used as wet flux. It is in powder form and applied by making a solution by dip prior to galvanizing.

FLUXOL 343 (BLANKET FLUX)

It is a very effective powder flux which is used over the molten zinc bath to cut off oxygen supply over the molten zinc and thus prevents oxidation of zinc as it forms a thin layer over the top of the molten zinc bath.

PASSIVATION CHEMICALS

Zinc is also a sensitive metal which forms white rust on exposure to air and moisture. The corrosion products give an unsightly, mottled surface consisting of the loose powder that makes it unfit for the industrial and domestic uses. White rust damages long-term protection of the base steel. Passivation of the galvanized surface is inevitable for long life of the articles.

ALIBOND 297 (HEXAVALENT )

It is a chemical process, which produces a protective colorless chromate conversion coating on galvanized iron and zinc-aluminum surfaces.

PASSILINE TC 1304 (TRIVALENT)

It is trivalent chromium based chemical process, which produces a protective almost colorless to very light bluish chromate passivating film on galvanized iron and zinc-aluminium alloy surfaces

PASSILINE NC 305 (NON -CHROME)

It is a novel technology for surface treatment that forms an anti-corrosive conversion coating on the galvanized / galvalume surface that imparts strong paint adhesion, humidity resistance and lubrication properties.