Electroplating Chemicals

Electroplating Chemicals

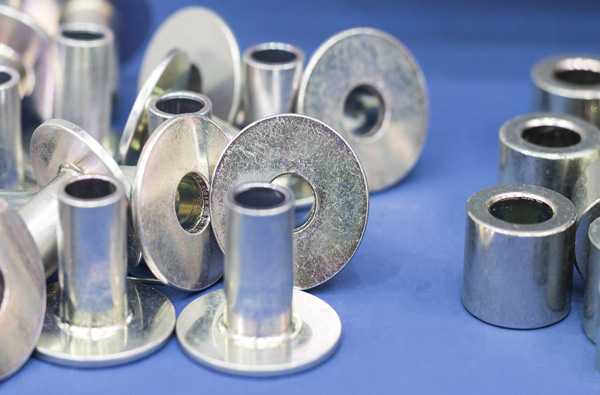

Electroplating is the process of coating a metal with a thin layer of another metal by electrolysis to improve the metal’s corrosion resistance. Electroplating is also known as electrodeposition and electroplated coating. The main purpose of electroplating is to improve appearance and protection against corrosion..

Electroplating is primarily used to change the surface properties of an object(such as abrasion and wear resistance, corrosion protection, lubricity, aesthetic qualities), but may also be used to build up thickness on undersized parts or to form object (such as abrasion and wear resistance, corrosion protection, lubricity, aesthetic qualities), but may also be used to buildup thickness on undersized parts or to form objects by electroforming.